Who is Your Inspector?

From Factory Floor to R&D Supervisor

“I am not a trader. I am a Polymer Engineer.”

Unlike commercial agents, I started my career operating extruders on the production line. I moved up to Quality Control and eventually became an R&D Supervisor.

This means I know exactly how suppliers might hide defects, use cheap fillers, or manipulate lab data. I act as your trusted technical eyes in Iran to ensure the material you pay for is the material you receive.

Our Core Services

Comprehensive Quality Control for Polymer Buyers

On-Site Visual Audit

Checking color, smell, and physical appearance to ensure no contamination, dust, or moisture affects the material.

Advanced Lab Verification (DSC, FTIR, Mechanical)

We go beyond basic checks. We supervise critical tests including MFI, Ash Content (TGA), DSC, Tensile/Impact, and Density. We analyze the results to ensure no cheap fillers, moisture, or polymer degradation exists in your cargo.

Loading Supervision

Monitoring the loading process, verifying net weight, and sealing the container to prevent cargo swapping.

Stop Paying for Hidden Fillers & Contamination.

We verify the purity of your polymer before shipment.

Technical Expertise

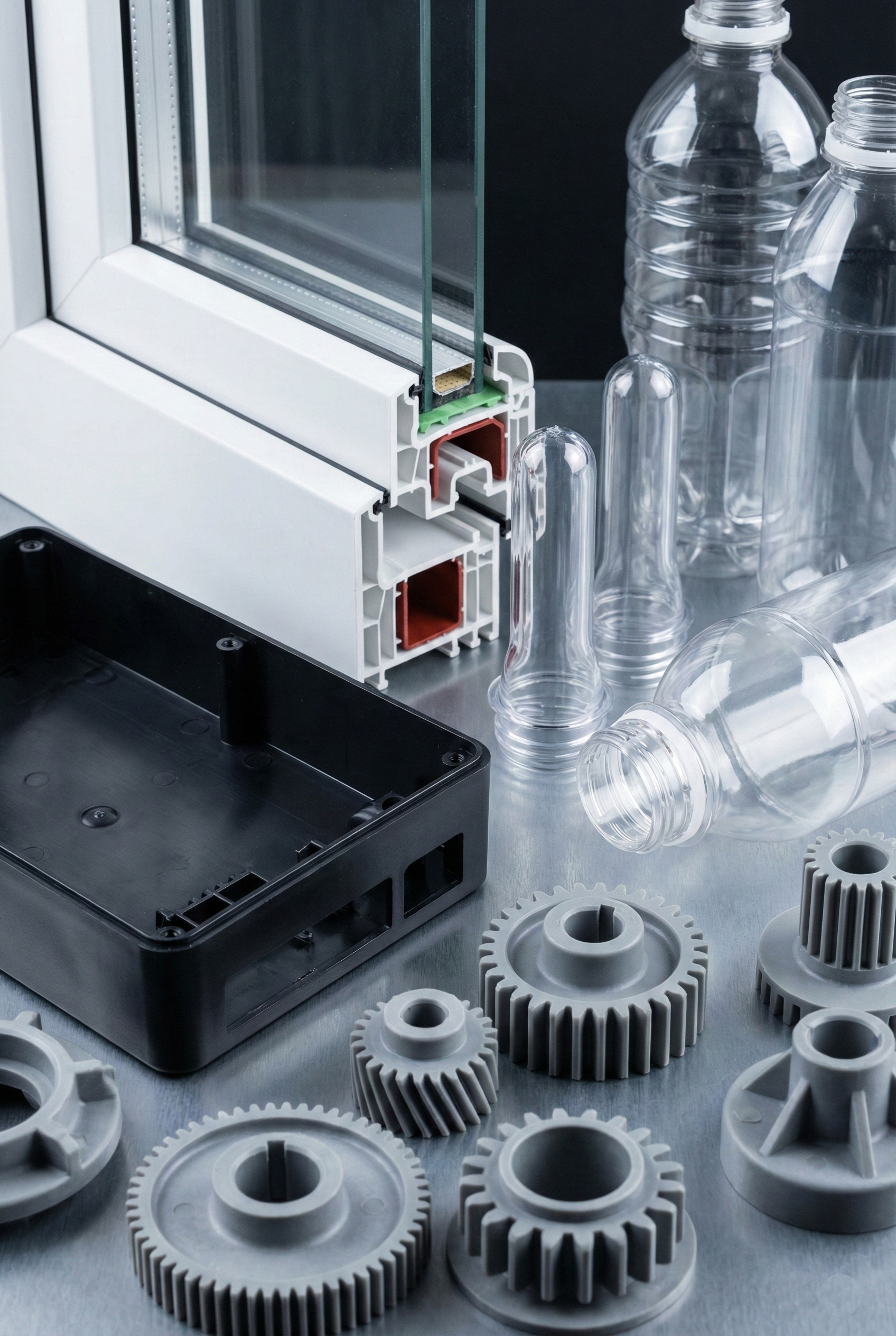

Materials We Inspect Daily

Polyethylene (PE)

Polypropylene (PP)